-

About us

-

Business

-

Product

-

Contact us

Future is on

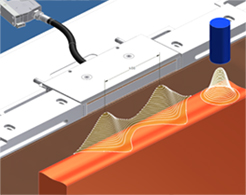

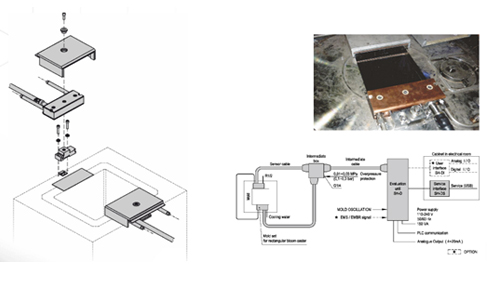

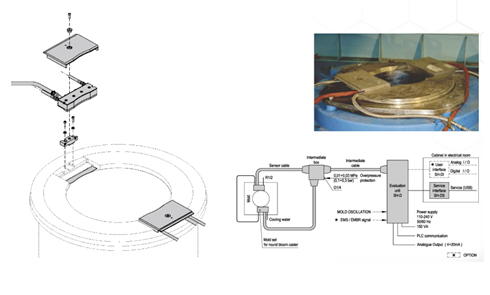

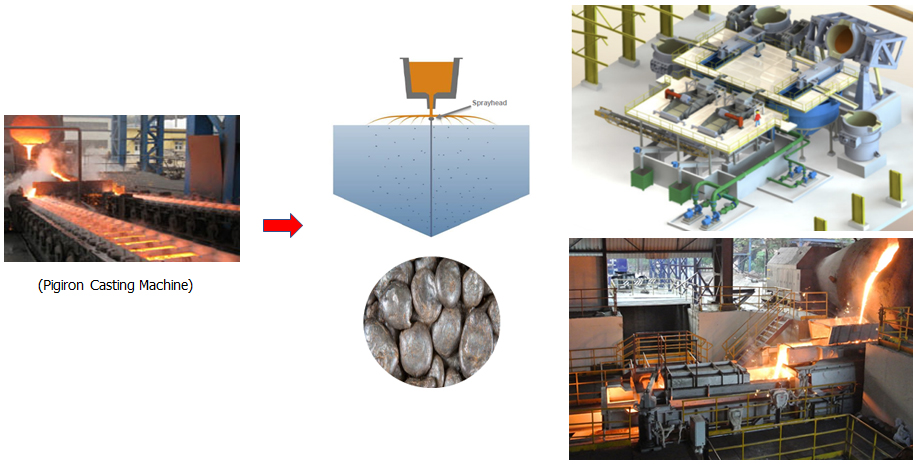

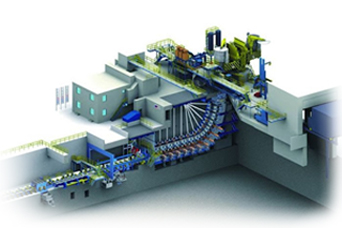

Ensuring stable operations at the BF is beneficial High Capacity GRANSHOT ensures stable BF operation

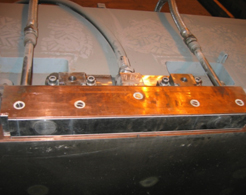

Ferroalloy producers find the GRANSHOT process attractive due to

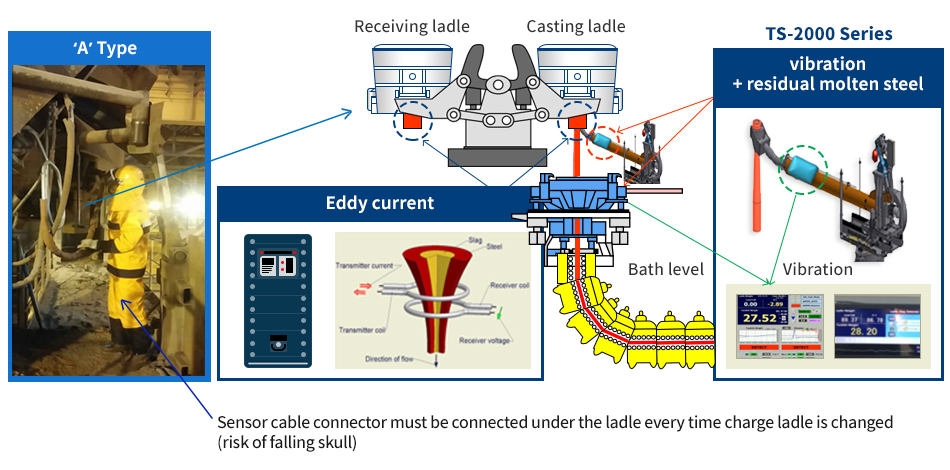

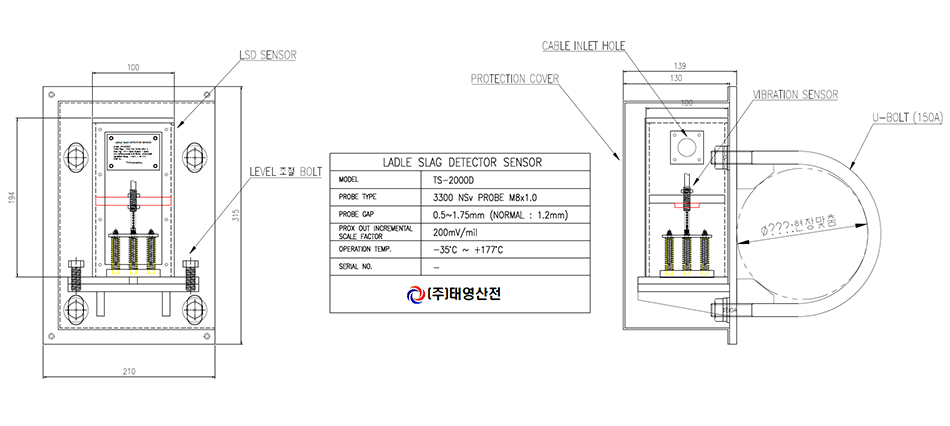

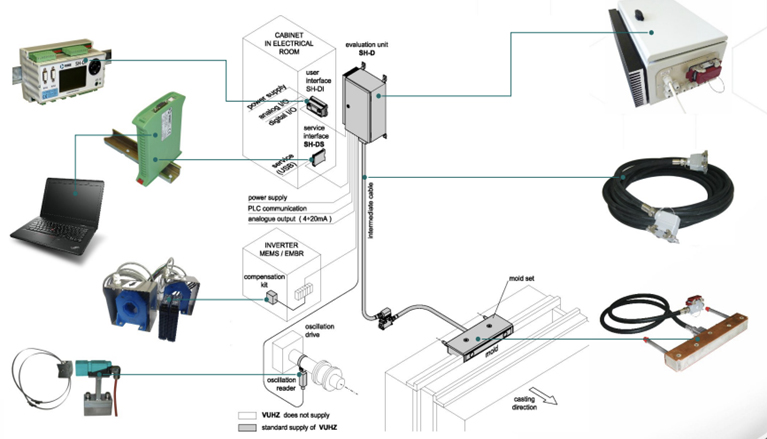

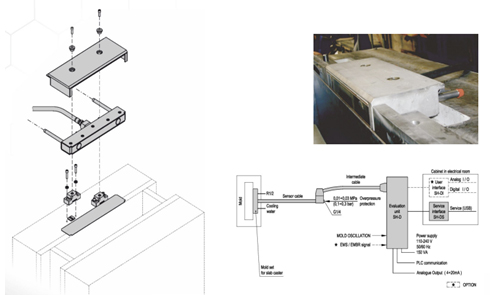

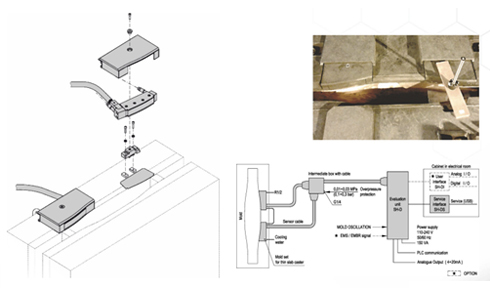

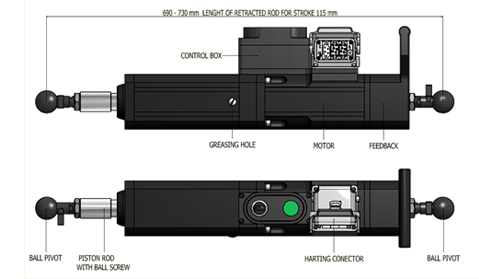

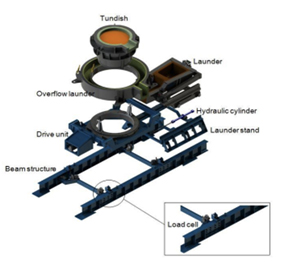

Optimized solution with high reliability compared to conventional vibration method

Operator action not needed